Docking "Made in China 2025" my countrys comprehensive launch of 3D printing standardization

Release date:2020-03-26

The First Financial Reporter learned from the National Standards Committee on April 21 that my country has fully launched the standardization of additive manufacturing (3D printing) in connection with "Made in China 2025".

The National Additive Manufacturing Standardization Technical Committee (SAC/TC 562) was announced in Beijing on the same day. Tian Shihong, a member of the AQSIQ party group and director of the National Standards Committee, introduced that the development of additive manufacturing and standardization have an important support and leading role. The establishment of the National Additive Manufacturing Standardization Technical Committee has promoted additive manufacturing technology and promoted additive manufacturing technology. The development of the industry is of great significance.

According to reports, to connect with major national plans and strategic deployments such as "Made in China 2025", "National Standardization System Construction and Development Plan (2016-2020)", "Equipment Manufacturing Standardization and Quality Improvement Plan", the newly established Standardization Technical Committee will strengthen standards Develop, implement and serve, speed up the training of technical personnel, management, and rules of composite additive manufacturing standardization personnel, actively participate in international standardization work, put forward high-quality, high-level standard proposals as soon as possible, and actively strive to serve as the leader of the International Standardization Organization Convener of positions and working groups to transform the advantages of China's additive manufacturing into international competitiveness.

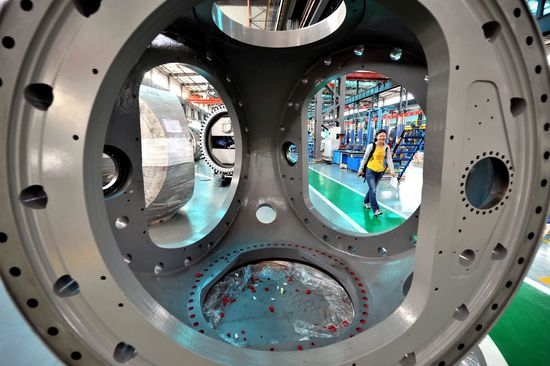

Academicians of the Chinese Academy of Engineering Lu Bingheng and Wang Huaming introduced that in recent years, China's additive manufacturing technology has developed rapidly. Light curing, selective laser sintering, selective laser melting, fused deposition forming and other processes and equipment have a good foundation, and some additive manufacturing technologies And products have been widely used in aerospace, biomedicine, cultural creativity, and other fields, and high-performance metal component additive manufacturing technology has reached the international advanced level.

Experts told reporters that standardization is of great significance for accelerating the industrialization of my country's additive manufacturing technology. "China's additive manufacturing field has shown a lot of standardization needs." Lu Bingheng believes that on the basis of formulating more high-quality national standards, actively propose more and better group standards to allow more high-quality, high-level, International companies and experts participate in the formulation of standards, promote the blooming of China's additive manufacturing standards, and promote the industrial development of China's additive manufacturing technology through standards.

It is understood that the chairman of the National Technical Committee for Additive Manufacturing Standardization is Lu Bingheng, an academician of the Chinese Academy of Engineering known as the "Godfather of 3D Printing in China", with a total of 61 members, basically involving representative universities and research institutes in the field of additive manufacturing in China , Enterprises, industry associations, etc., the scope covers many fields such as technology, materials, equipment, services, testing, certification and medicine.

Since my country became a P member of the ISO/TC 261 Additive Manufacturing Technical Committee of the International Organization for Standardization in 2014, breakthrough progress has been made in my country's additive manufacturing standardization work. The experts put forward a technical standard system that conforms to the current state of technology development in my country and covers the entire industrial chain of additive manufacturing. In terms of basic terminology, processes and materials, typical processes and test methods, 6 national standards have been established, and experts are recommended to become experts in ISO/TC 261, effectively participating in the international standardization of additive manufacturing.

Tian Shihong believes that the establishment of the National Additive Manufacturing Standardization Technical Committee is a milestone in my country's additive manufacturing technology development and standardization work. It is reported that the standard committee will gather a group of first-class enterprises, universities and research institutes in the field of additive manufacturing, gather a group of high-level technical experts, and build a technical platform that integrates standardization research, application, communication and sharing. While enhancing the effective supply of additive manufacturing standards, it will effectively raise the international level of China's additive manufacturing standards, give play to the leading effect of "standardization +", accelerate the construction of a strong manufacturing country, and help China's product industry move towards the mid-to-high-end level.

Standardization is of great significance for accelerating the industrialization of my country's additive manufacturing technology.

English

English 中文

中文